Contents

COST REDUCTION IN CEMENT INDUSTRY BY Amjad Waqar

CLICK HERE TO DOWNLOAD MOST IMPORTANT INTERNAL MANUALS , EXCEL CALCULATION SHEETS & REFERENCE BOOKS FOR ENGINEER WHO WORK AT LAFARGE HOLCIM , FL , CEMEX

Cement industry is one of the highest capital-intensive industry; and has direct correlation with economic growth and improvement in the living standard of the society.

With ease of international trade and increasing local competition, sustainable cost reduction in cement manufacturing is imperative, not only to be competitive among the industry players but also to increase profitability of the Company.

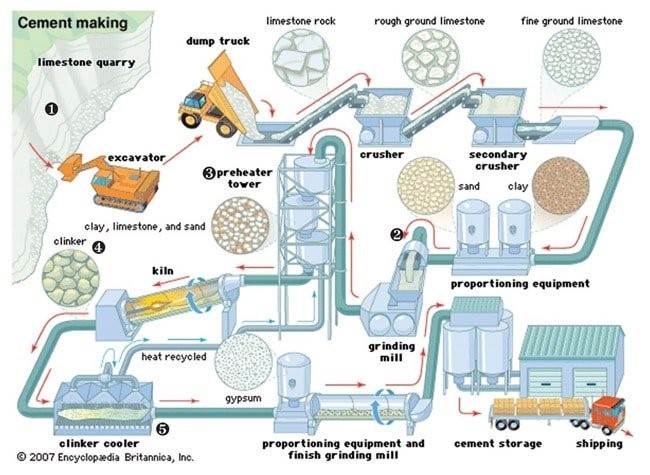

Based on my experience and achievements in reducing cost in various organizations, I believe that Sustainable cost reduction is possible in each area of Cement production and in value chain of a Company. For understanding, a typical production process of cement manufacturing illustrated below (illustration by Encyclopedia Britannica):

As per my understanding, three (3) areas contribute approximately 55 to 60% cost of Cement production, namely:

1- Fuel : (may it be Coal, Pet Coke, Furnace Oil, Diesel, Alternative Fuels etc.)

2- Power : (through Grid, WHR or self-generation via coal, gas etc.)

3- Logistics : (both inward & outward)

For any cost reduction in cement industry, it is imperative to control these areas, which automatically results in increasing profitability of the Company.

Beside these three (3) areas continuous improvement and cost reduction is key for success, below we discuss in detail some of the critical areas involved in Cement production with an objective of Cost reduction and efficiency improvement.

Raw Material, Crushing & Raw Meal:

Limestone is an essential raw material for cement manufacturing; a production process typically starts with extraction of Limestone from the quarry, other raw material including clay, sand, shale etc. are either been extracted as per availability in quarries or being procured.

Cost Reduction opportunities in areas:

There are several areas where cost can be reduced including not limited to;

a) Limestone and other raw materials extraction cost (insourcing, outsourcing)

b) Extraction equipment maintenance

c) Royalty and extraction terms

d) Procurement of other raw materials and their sourcing

e) Procurement terms

f) High time / low time for procurement

g) Transportation mechanism

h) Raw Material Crushing, sizing of raw material for crushing etc.

i) Maintenance of Crusher

j) Raw Meal Mix

k) Stock levels and

l) Contingency

Kiln / Clinker Production & Fuel Mix

Continuous production is one of the critical requirement for operating kiln and maintaining clinker production cost; some of the key areas for Cost Reduction opportunities includes;

· Fuel efficiency & its mix

· Purchase terms

· Holding & Hedging cost

· Alternate Fuel availability & usage

· Storage, Transportation & Handling

· Number of Startup / Shut down & associated cost

· Procedure for Kiln Start up

· Fuel Consumption during start ups

· Refractory bricks, their life & replacement strategy

Electricity Usage

Fuel & Electricity is one of the major component of Cost of Cement production, Cement production requires electrical power at several stages, from crushing of raw materials over clinker production and cement grinding.

Following are some areas, which can help in reduction of electricity cost.

· Waste heat recovery

· Utilization and motor factors (including calibration etc.).

· Current Electricity usage VS International best practices

· Carbon Capture & Credits

· Peak electricity demand, rates & utilization

· Co-production of electricity & cement and use of Fly Ash

Preventive Maintenance Vs Breakdown Maintenance

As discussed above continuous production is essential and each breakdown not only results in higher maintenance cost but also in loss of revenue due to loss of production.

Development of preventive maintenance plan is essential for smooth operations, areas to consider for effective cost reduction include:

· Monitoring number of Breakdown per week / per month and reasons

· Lubrication & its cost

· Balancing of motors and equipment

· Production losses and breakdown cost

Cost of Financing & Working Capital

Being one of the most capital-intensive industry, managing cost of financing and working capital is one of the prime element in product costing, simultaneously, it provides a good opportunity to review and take steps to reduce its cost.

Some of the areas where cost can be reduce includes:

· Current Financing Structure and its cost

· Short term VS Long term financing arrangement

· Utilization of rebates & discounted financing arrangements

· Working Capital Management and Stock holding cost

· Exchange impact & Hedging

· Placement of funds and savings

Summary

The areas discussed above are of most critical nature and several companies benefited with cost reduction while controlling these areas.

Cost reduction is possible and viable in other areas as well including but not limited to (1) Distribution system and maintaining effective net selling price / retention (2) Competitive Procurement (3) Packaging (4) Right Staffing / Right Mix of Human Resource (5) Effective Tax Planning (6) Managing Duties & other levies (7) Controlling expenditure on legal suits and many more, list goes on….

Author

The Author is a Financial & Business expert with approximately fourteen (14) years of professional experience in streamlining operations, drive performance, reduce costs and transform organizations, being CFO of Pioneer Cement Ltd he played pivotal role in transforming Company; for which the Company has been bestowed with Award in CFO Conference 2014 under CREI (Cost Reduction and Efficiency Improvement) category.

Hi